ATEX are European Union directives describing what equipment and work space is allowed in an environment with an explosive atmosphere. ATEX is an abbreviation in French for ATmosphères (Atmosphere) and EXplosible (Explosive).

ATEX consists of two EU directives:

- The Directive 2014/34/EU: relating to equipment and protective systems intended for use in potentially explosive atmospheres

- The Directive 99/92/EC: Minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres.

CENELEC – European Committee For Electrotechnicals Standardization and European standards (ENs)

The 2 ATEX Directives contain the requirements in general not the details in technical how to prevent the explosion. According to the Directives, the technical details are on based on the standards which help to convince the government about the law compliances to prevent the explosion in potentially explosive atmospheres.

As it took time and efforts to create new standards, CENELEC harmonized the series standards of The International Electrotechnical Commission (IEC) and created the series ENs. ENs are documents that have been ratified by CENELEC to be implemented in EU.

How the ENs are named was similar to IEC standards. For example: The IEC standards which were named IEC 60079-0 for marking equipment became harmonizes standards EN 60079-0 or IEC/EN 60079-0.

The harmonized standards ENs provided the technical requirements in detail to prevent explosion. As it was difficult for the factory owners to understand and know how to comply with those requirements, they usually ask for the consultancy from the experts who are competent in Ex like the experts who are working for Trainor to reduce costs and improve safety at potentially explosive atmospheres.

What is ATEX Certififcation?

Equipment manufacturers whose products are intended to be used in Europe are responsible for making sure their equipment complies with ATEX standards. This process involves conformity assessment procedures and certification by a third party called a “Notified Body" such as DNV, Presafe, NEMKO.

The ATEX certification is issued for the equipment intended for use in potentially explosive atmospheres not for the personnel who work with the equipment.

Comparison Table of Explosion-proof Standard

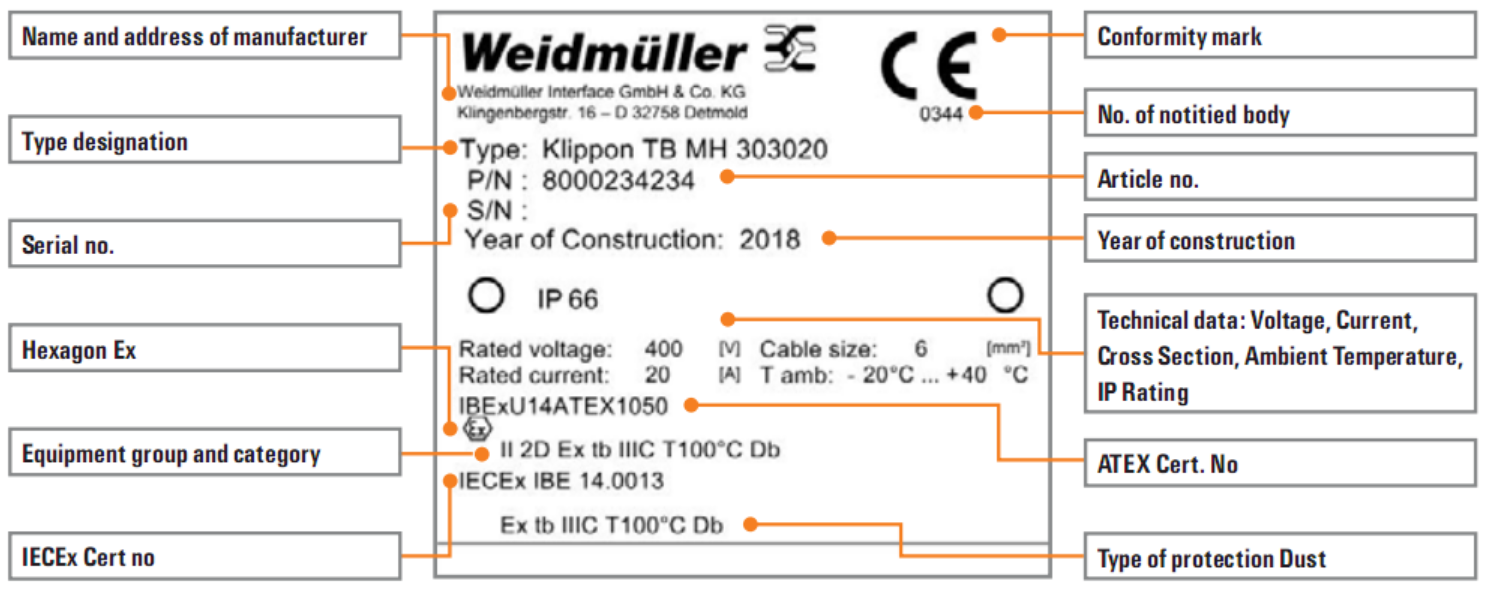

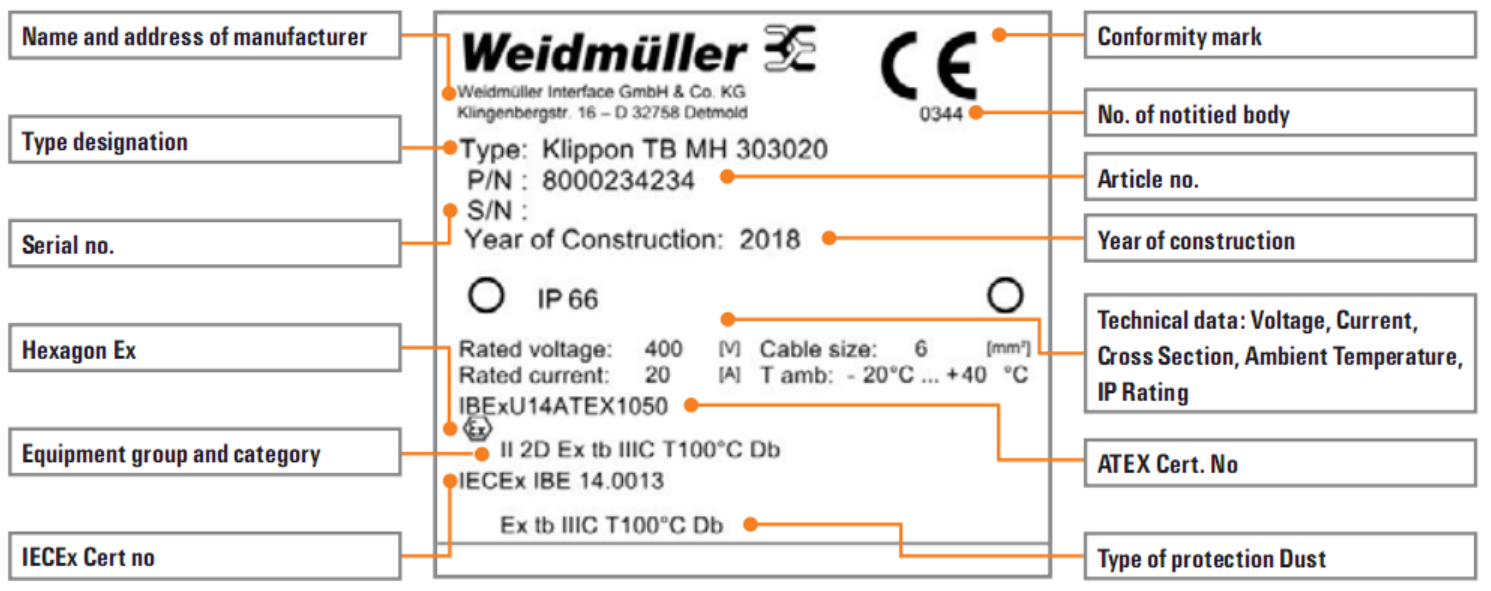

Example of the marking for a Weidmuller junction box

|

TIIS-1979 (Japan) |

IEC & CENELEC (Europe) |

USA & Canada |

|

|

Based Standard |

VDE 0170/0171 NFPA 1978 IEC 79-0 - 12 |

IEC 79-0 - 14 EN 50020/50039 |

NFPA 70-1987 ANSI/UL 913-1988 FM 3610 CSA C22-1986 |

|

Hazardous Locations and Applicable Type of Explosion-proof |

Class 0: I only Class 1: I, d and f Class 2: I, d, f, e and o Dust under Consideration |

Zone 0: ia only Zone 1: ia, ib, d and f Zone 2: ia, ib, d, f, e and o Dust under Consideration |

Class I, Div.1: equivalent as Class 0 & 1, Zone 0 & 1 Class I, Div.2: equivalent as Class 2, Zone 2 Class II: Dust |

|

Type of Explosion-proof |

Flameproof : d Pressurized : f Increased safety : e Intrinsic safety : I Oil-immersed : o Special : s |

lameproof : d Pressurized : p Increased safety : e Intrinsic safety : ia/ib Oil-immersed : o Encapsulation : m Special : s |

Not categorized by Types |

|

Gas and Dust Classification More easily ignited |

1 : Propane 2 : Ethylene 3a: Hydrogen 3b: Carbon disulphide 3c: Acetylene 3n: All vapors in class 3 Dust under Consideration |

II A: Propane II B: Ethylene II C: Hydrogen II C: Acetylene Dust under Consideration |

Class I Group D: Propane Class I Group C: Ethylene Class I Group B: Hydrogen Class I Group A: Acetylene

Class II Group G: Flour, Grain Class II Group F: Carbon dust Class II Group E: Metal Dust |

|

Temperature Classification (Ignition temperature of Applicable gas or vapor) |

G1: over 450 C G2: over 300 to 450 C G3: over 200 to 300 C G4: over 135 to 200 C G5: over 100 to 135 C G6: over 85 to 100 C |

T1: over 450 C T2: over 300 C T3: over 200 C T4: over 135 C T5: over 100 C T6: over 85 C |

T1: over 450 C T2: over 300 C T3: over 200 C T4: over 135 C T5: over 100 C T6: over 85 C |

|

Code Example |

d2G4 |

Ex d II BT4 |

Class I, Div.2, Group C D, T4 |

|

i3aG5 |

Ex ia II CT5 |

Class I, Div.1, Goup B C D, T5 |

(NOTE: TIIS means Technology Institute of Industrial Safety, Ministry of Labor, Japan)

eg. d2G4

d: Shall be used at Class 1 and 2 locations

Equivalent as Zone 1 and 2, Class I Div. 2, and Div.1 with special conditions

2: Can be used for both 1: propane and 2: Ethylene

Equivalent as T4(=T6, T5 and T4)

G4: Process temperature is less than G4 (=G6, G5 and G4)

Equivalent as T4 (=T6, T5 and T4)

Documentation:

Eaton Crouse-Hinds Principles of Explosion Protection

Eaton Crouse-Hinds Principles of Explosion Protection

(From Internet)