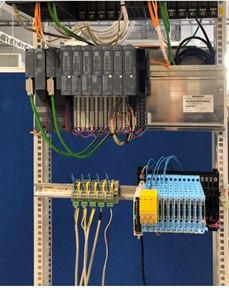

Successful Proof of Concept – SIMATIC ET 200SP HA and MTL SUM5

On 30th of March 2021 the Proposal Center of the Process Automation Solutions entity within Siemens Digital Industries demonstrated the verified functionality of MTL SUM5, smart universal marshalling module, in connection with the new configurable SIMATIC ET 200SP HA I/O card family. The involved team, consisting of members of the business unit Process Automation within Siemens AG Digital Industries and MTL Industries GmbH were satisfied as it worked perfectly! Proof of concept successful!

What were the drivers?

MTL Instruments GmbH, an Eaton company, and Siemens AG are looking for a long-term business relationship in the solution business. When Hermann Mueller, bid manager within the above-mentioned Proposal Center at Siemens, joined the market launch of the MTL SUM5, he directly recognised the technical capabilities and contacted Marcel Hilger, Key Account Manager at MTL Instruments GmbH.

Marcel Hilger supplied two MTL SUM5 modules so the preparations could start. Firstly, a typical wiring scheme had to be developed as the MTL SUM5 had never been connected to SIMATIC ET 200SP HA before. This task was solved by the Siemens “Global Engineering Center” in India. Furthermore, a test environment needed to be established and test scenarios created. Olaf Schnur from Vertical Management Chemical Industry of the Process Automation Solutions entity within Siemens Digital Industries had successfully taken on this challenge. As soon as everything was working, all involved parties had been invited to “Proof of Concept” to demonstrate all functions.

Why and for what?

In process controlled plants in the chemical and other industries, all process signals like pressure, temperature, flow as well as actuating signals for valves and drives are exchanged via input/output cards from the process control system to peripheral devices. Depending on the requirements, there will be binary inputs (e.g. valve feedbacks), binary outputs (e.g. command on/off) or analogue inputs (e.g. flow, pressure and temperature measurement).

In process controlled plants in the chemical and other industries, all process signals like pressure, temperature, flow as well as actuating signals for valves and drives are exchanged via input/output cards from the process control system to peripheral devices. Depending on the requirements, there will be binary inputs (e.g. valve feedbacks), binary outputs (e.g. command on/off) or analogue inputs (e.g. flow, pressure and temperature measurement).

These signal types must be defined at the beginning of plant configuration and hard wired. Later changes, when needed, require significant effort to implement. For these reasons Siemens designed new configurable I/O cards into their new SIMATIC ET 200SP HA family in order to make these signal types configurable.

MTL Instruments GmbH did the same with their new MTL SUM5 modules. As soon as both components are connected all signal types will be configurable without any changes in wiring during entire runtime of the plant.

Why do we need MTL SUM5 modules? Why no direct connection to the I/O cards?

The reasons are better maintainability and the requirement of galvanic isolation between each signal. In the case of disruption e.g. fault of a transducer, the loop needs to be disconnected and analysed without disruption to any other signals on same IO card (mostly 16 channels). Also, a short circuit of one signal should not interfere with any other signals. In former times these demands would be realised with a huge effort of wiring and a multitude of components like amplifiers, terminals and diodes.

With the MTL SUM5 only one module is required, connected with a pre-configured cable to the I/O card on one side and a field cable to transducers and drives connected on the other side.

“That means even a plant with 10,000 I/O signals requires only one wiring typical to cover the signal types analogue input, binary input and binary output” Marcel Hilger resumed. “Detail engineering could be done with a laptop and software changes don’t require wiring changes in the cabinets”.

What about the customer’s benefit?

For the end customer and the user, it means less space requirement for cabinets and less susceptible components. Also, more flexibility for changes and rebuilds.

MTL Instruments calculate the savings, accounting for space and cabinet requisition, potentially up to 70%.

MTL Instruments calculate the savings, accounting for space and cabinet requisition, potentially up to 70%.

For planner and plant designer it means time saving and greater flexibility, because each detail does not have to be fully defined from the beginning. Therefore, other dependencies and throughput times could be drastically reduced. The term: “More later more costly” for changes has lost its significance!

What about benefit for Siemens and MTL Instruments?

Both companies are focused on the customer’s benefits. “A customer in solution business buys our solution with our products, so he can run his production more flexible and efficient, better and safer” says Miriam Stricker, head of the Proposal Center of the Process Automation Solutions entity within Siemens Digital Industries in Karlsruhe. ”...means when he has benefits” adds Ulrich Künzli, Sales Manager at MTL Instruments GmbH. In this case both companies have combined their newest products to an innovative solution.

Left: Miriam Stricker, Head of the Proposal Center of Excellence within the Process Automation Solutions entity at Siemens Digital Industries in Karlsruhe.

Right: Hermann Mueller, Bid Manager of the Proposal Center of Excellence within the Process Automation Solutions entity at Siemens Digital Industries in Karlsruhe Testing area in the background.

Contacts:

Miriam Stricker

Siemens AG

Digital Industries

Process Automation

Proposal Center of Excellence

DI PA SE&C SO PCE

Email: miriam.stricker@siemens.com

www.siemens.com

Marcel Hilger

Eaton

MTL Instruments GmbH

Crouse-Hinds Division

Email: MarcelHilger@Eaton.com

www.eaton.com

www.mtl.de

(April 29th, 2021)