- Call Us (+8428) 3811 0510

- Email info@vtltech.com.vn

- Contact Us

Faure Herman Ultrasonic Flowmeters

ULTRASONIC FLOWMETER TECHNOLOGY

Utilizing our know-how and leading position in liquid metering, we have developed ultrasonic flowmeters both for custody transfer and process applications based on cutting edge technology.

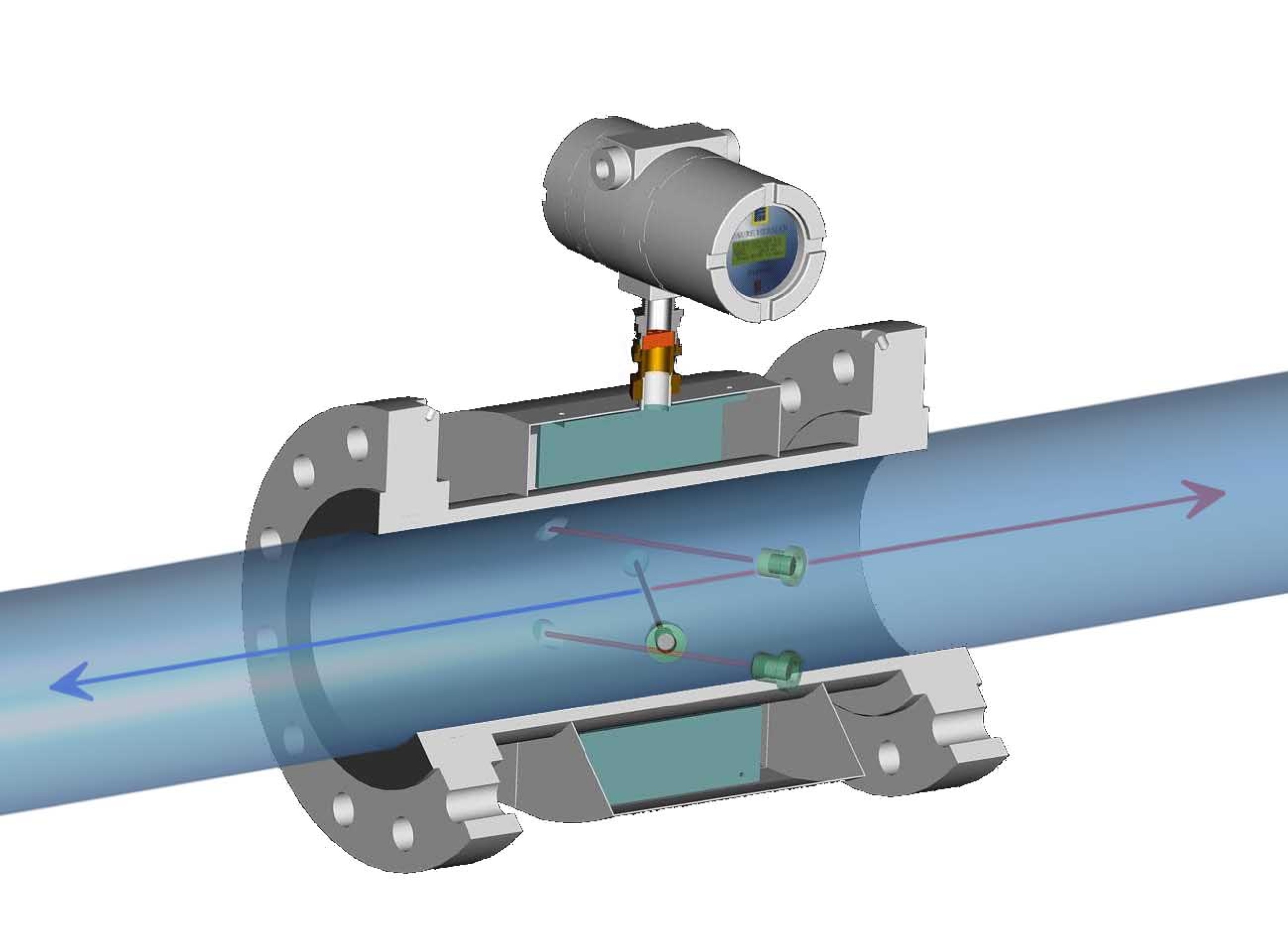

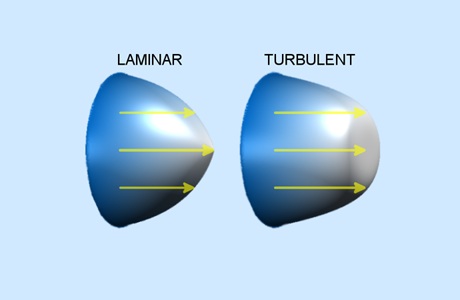

The FH8000 ultrasonic flowmeters measurement is based on the ultrasonic transit time method.

| MAIN FEATURES | BENEFITS |

|---|---|

| Full bore body, no pressure drop | Operating cost reduction |

| No moving parts | Operating cost reduction |

| Superior linearity (+/- 0.15%) over a wide range of viscosity | Reduced installation costs and foot print (CAPEX)Accurate measurements = Reliable income |

| Reliable and stable in severe conditions such as wax, sand, DRA, … | Reduced maintenance costs (OPEX)Accurate measurements = Reliable income |

| Low pressure drop | Reduced operational (energy) costs (OPEX) |

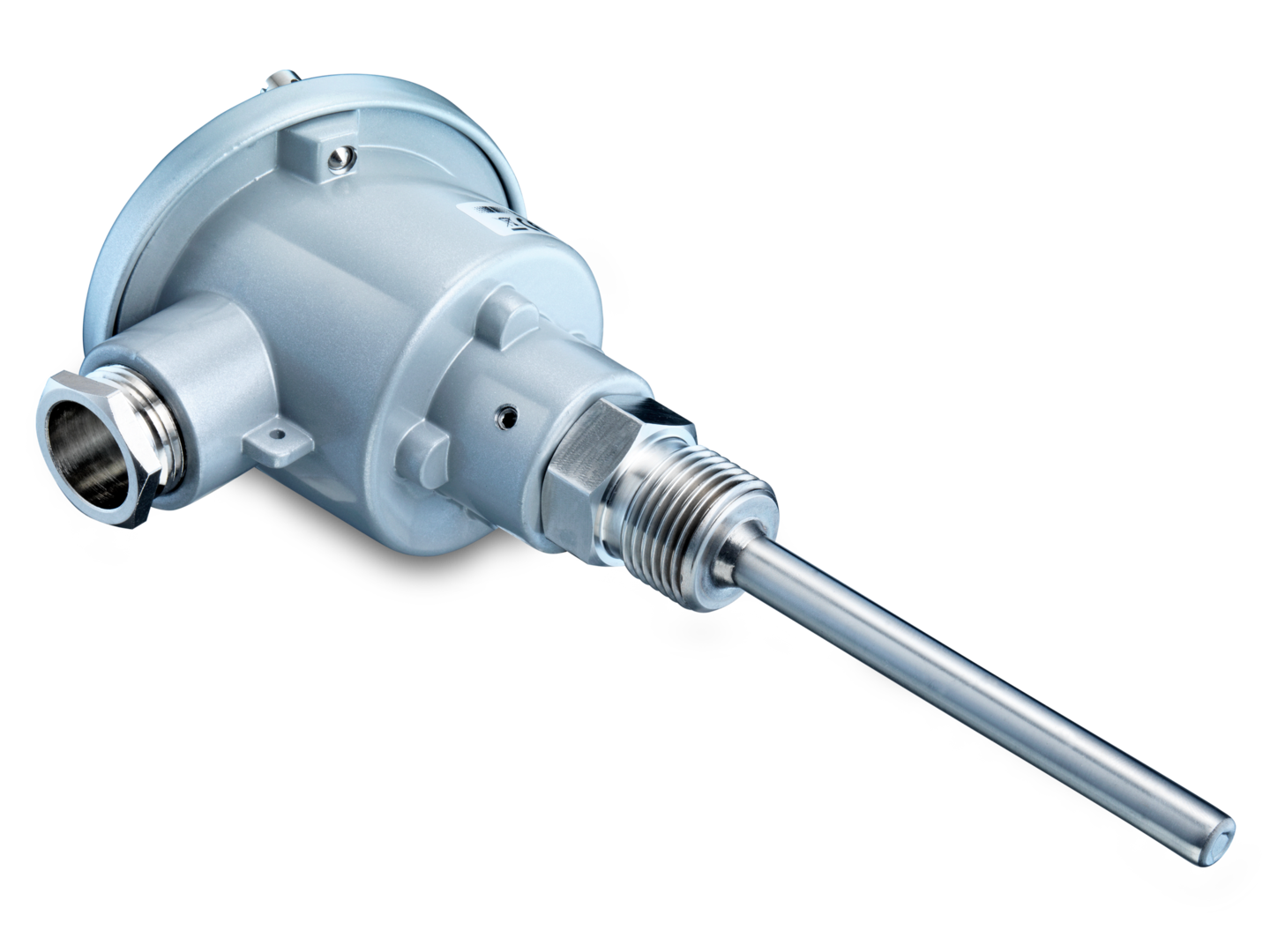

FAURE HERMAN ULTRASONIC FLOWMETERS FH8400

Main applications

Oil production, pipeline leak detection, oil refineries, chemical & petro-chemical plants, energy / power plants, water & wastewater, other process industries

Key customer advantages

-

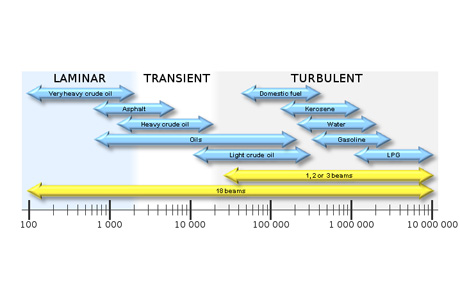

3 beams

-

Bi-directional measurement

-

Calibration in Reynolds

-

No pressure drop

-

Removable transducers under pressure and flowing conditions

-

Lower cost of ownership

Performances

-

Bidirectional flow

-

Viscosity range up to 180 cSt approx.

-

Meter size: 3″ to 24″

-

Smart remote software FHview

ATEX, PED, EMC certified

Faure Herman VietNam